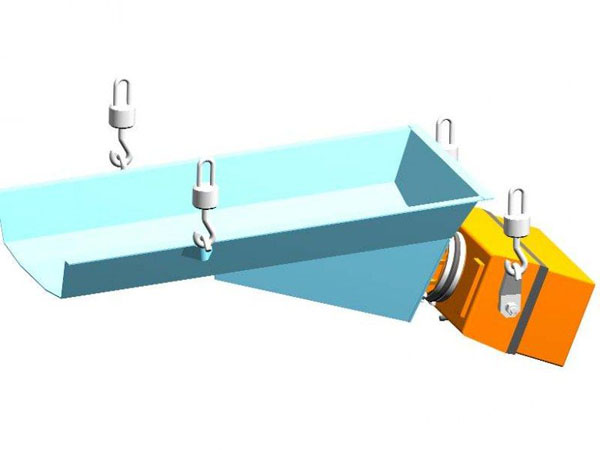

Flat vibrating feeder with electro-magnetic PWP

Flat vibrating feeders with electro-magnetic drive are designed for transport and dosage of loose materials.

Question about a product

Flat vibrating feeder with electro-magnetic PWP

Advantages:

- ability to dose and weigh media

- compatibility with scales

- works well during continuous and interrupted operation

- act as sealing elements of the container

- ability of performing a dustproof process

- ability of stepless capacity adjustment in the rage from 0 to max.

Technical description:

Flat vibrating feeders with electro-magnetic drive are designed for transport and dosage of loose materials. Applied under the outlets of containers or silos, they simultaneously act as their enclosing elements. Feeder capacity adjustment in the range from 0 to max allows for their application as dispensers in feeding and batch systems in various branches of industry. The vibrator is supplied via with power a thyristor-controlled power supplier allowing for adjustment of the output voltage during operation, and thus the adjustment of the vibrator’s vibration amplitude. Thyristor-controlled power supplier also allows for remote control of processing. The feeder’s trough can be additionally covered with e.g. plastic, rubber or wear lining.

Vibrating electro-magnetic feeders are made of the following sets: flat troughs with suspensions – shock absorbers, electro-magnetic vibrator and thyristor-controlled power supplier. Electro-magnetic vibrator is the source of vibrations transferred to the trough’s structure, causing movement and flow of material. Vibration rate (amplitude) is adjusted by voltage variation on the clamps of the vibrator’s electro- magnet. Alteration of the voltage rate is made with the use of a switch on a potentiometer located on the housing of the thyristor-controlled power supplier. The thyristor-controller power supplier has two switchable adjustment ranges for the voltage rate (transport and dosage) as well as the ability to remote control processing. Immediate halting of the transported material takes place after turning off.

Upon request of the Customer, all elements in contact with the fed material can be performed from stainless steel or other materials.

For the best selection of the equipment please contact our technical office, tel.: +48 77/470 04 97.