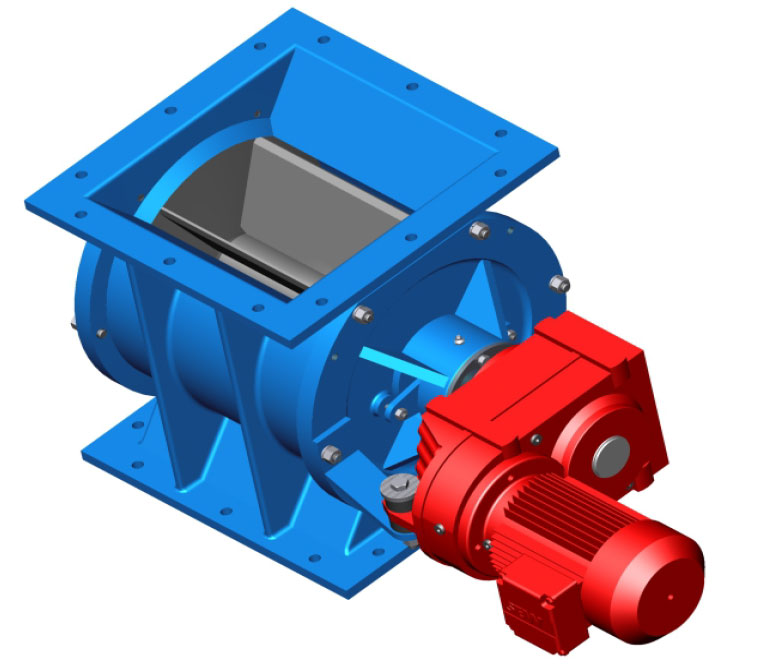

Ceramic rotary dispenser type DC

The main purpose of the ceramic rotary dispenser is tight sealing of containers in operation under pressure other than atmospheric pressure and allowing their emptying without decompression.

Question about a product

Ceramic rotary dispenser type DC

Intended use:

The main purpose of the ceramic rotary dispenser is tight sealing of containers in operation under pressure other than atmospheric pressure and allowing their emptying without decompression. It is used in dedusting installations, aforementioned emptying of containers and transport of dry dust, where dust and gas is not aggressive as well as where dust cannot develop an explosive mixture in contact with air. The dispenser is simultaneously a protection system (passive cut-off system), the purpose of which is effective deterrence of spread of explosions and fires which can take place in the dust collector/container or receipt system. During its operation the material (i.e. dust, coal dust, sawdust, cement, etc.) flowing from the container through the dispenser inlet is transported in cells between the blades of the dispenser’s rotating rotor and is discharged through the outlet. The rotor blades act as hatches sealing off the air flowing through the dispenser, therefore preventing decompression of the container.

Technical description: Ceramic rotary dispenser is powered with a motoreductor embedded on the rotor shaft. Dispenser’s rotor and body are made in a cast or welded edition. The motoreducer is chosen depending on the dispenser capacity. It is possible to use a rate inverter, thus allowing to obtain accurate dosage of material from the container.

For the best selection of the equipment please contact our technical office, tel.: +48 77/470 04 97.