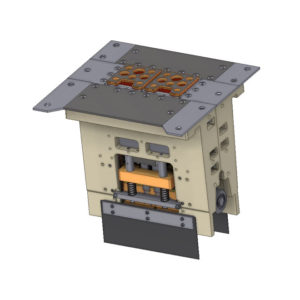

Moulds and tooling for moulds

Our experience in the industry is over 130 years of tradition. The best offers and innovative designs find interest of each of the leading silicate brick producers. Our products allow to maintain a strong and competitive position on the market of silicate blocks production. We provide the highest quality, mould…

Question about a product

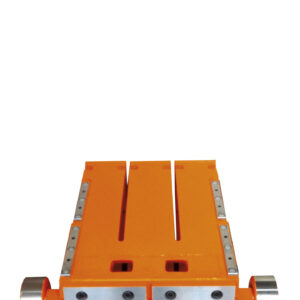

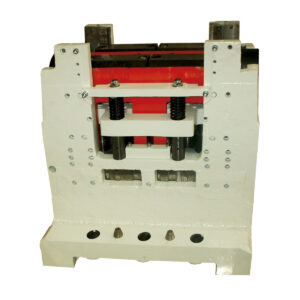

Moulds and tooling for moulds

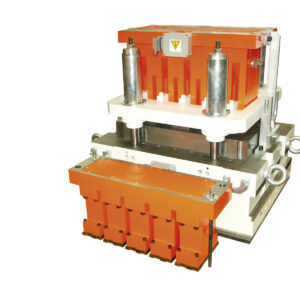

Our experience in the industry is over 130 years of tradition. The best offers and innovative designs find interest of each of the leading silicate brick producers. Our products allow to maintain a strong and competitive position on the market of silicate blocks production. We provide the highest quality, mould fillings as well as complete moulds for all types of presses, and all brick formats. We design and manufacture in accordance with the latest standards.

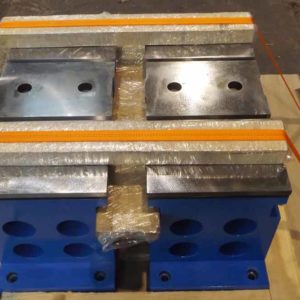

Our standard production program includes all necessary elements of mould fillings based on Atlas, Dorstener and others.

The advantages of our parts and components:

- produced with the highest precision, they guarantee the quality of the produced silicate blocks,

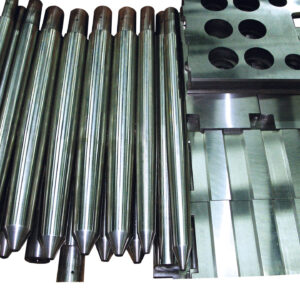

- thanks to thermo-chemical treatment, they are characterized by high resistance in difficult work conditions

- high durability of materials increases the lifetime of production cycles,

- we only use certified steel grades for production,

- our parts and components can be made specially according to your guidelines.

Ofama Sp z o. o. is a producer of complete moulds as well as parts of plating for presses producing lime-sand brick and refractory shapes. We make individual elements of mould fillings as well as complete forms, including additional equipment components such as slats, slides, heads, stamps, frontal side plates, partition plates and many more. Our production also includes drill elements, such as punches, which are mechanically shaped and precisely grinded to meet the technological requirements of our customers. We also provide complete moulds along with all the equipment for the production of silicate precast products. Mould plates are made of high-quality steel, which is delivered to us directly from the mills with the relevant certificates and approvals. Every time after production, each detail undergoes detailed quality control including hardness and resistance to deformation. We make many typical parts according to the workshop documentation as well as those given to us directly from Customers. We also do stocktaking and make reconstruction of individual parts from worn out press elements, mould plates and moulds.